8FT Automatic Veneer Peeling CNC Machine for Plywood Woodworking Machinery Line

Overview Package size per unit product 560.00cm * 210.00cm * 200.00cm Gross weight per unit product 7500.000kg Product D

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 8ft |

| Automatic | Automatic |

| Certification | CE, ISO |

| Processing Wood Length | 1970mm--2600mm |

| Processing Wood Diameter | Max500mm--Wood Core 30mm |

| Processing Thickness Range | 0.3mm--4mm |

| Main Motor Speed | 45m--80m Adjust Speed |

| Transport Package | Other Packing |

| Specification | 4300*1600*1900mm |

| Trademark | real gold/rotategold |

| Origin | China |

| HS Code | 8465960000 |

| Production Capacity | 300pieces/Mounth |

Packaging & Delivery

Package size per unit product 560.00cm * 210.00cm * 200.00cm Gross weight per unit product 7500.000kgProduct Description

| Item | Unit | Parameter |

| Processing wood Length | mm | 1970mm--2600mm |

| Processing wood diameter | mm | MAX500mm--wood core 30mm |

| Processing thickness range | mm | 0.3mm--4mm |

| Main motor speed | m/min | 45m--80m adjust speed |

Main and auxiliary motor power | kw | Double roller motor 7.5kw+7.5kw, single roller motor 7.5kw+7.5kw |

| Feeding motor 11kw servo motor | ||

| Clipper motor 4kw servo, rubber roller motor 4kw | ||

| Reducer model selection | R87 | Host with hard tooth surface reducer |

Main function | Imported guide rail cylinder wood core and tail presssing plate function | |

| Alloy rod and tin bronze nut | ||

| Taiwan Shangyin linear guide rail | ||

| Applicable to all kinds of high-precision panel rotary cutting | ||

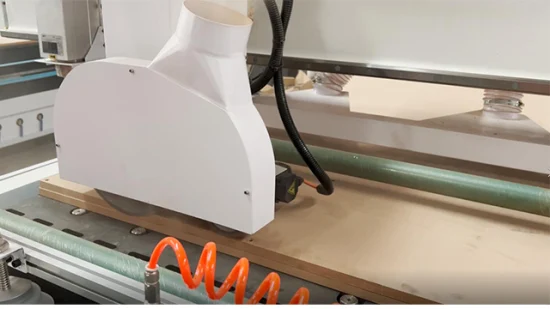

Detailed Photos

Company Profile

Our company has been committed to the research and development and manufacturing of plywood equipment, with 17 years of production and manufacturing foundation, improving the old production process of nearly a hundred years is our core purpose, adhering to the policy of "focusing on rotary cutting, serving the world, and after-sales for life". More than 100 national patents, the main products are rotary cutting machine and peeling and rounding machine, self-developed veneer rotary cutting vacuum board assembly line, high-end furniture board intelligent one-time forming line, thick core board rotary cutting and drying one-step forming line and other advanced equipment Leading domestic level.

Certifications

The company participated in the formulation of three national industry standards, and passed the ISO9001 quality management system, measurement management system and EU CE certification.

Customer Factory

The company specializes in the production of high-speed non -card shaft rotary tangent lines, high precision double-sided light combined rotary tangent lines,and provides planning solutions for plywood factories, particleboard factories,etc.The specific specifications of wood saws can be customized according to individual needs.

Packaging & Shipping

Since 2016, the company has successfully exported to more than 50 countries such as the United States, Canada, Brazil, Russia, etc., and is well received by foreign customers. Now it is a well-known enterprise in the industry with an annual output value of nearly 100 million yuan, and its advanced equipment is far ahead in the industry.The company has its own unique R & D team, each product is condensed workers' wisdom and efforts, product quality is guaranteed.

Cooperation show

Why choose us

1.Equipment design long service life, good stability,all accessories are well-known brand products at home and abroad,high quality,low failure rate.

2.The board surface effect is good,smooth on both sides,high uniformity,in the same specifications of the board, our company's output of the board price advantage is obvious.3.Fast speed of equipment,high output, smooth operation of production line,scientific and close connection of each part,to ensure smooth operation under the condition of high speed production. 4.Save labor,in the past old equipment a drag a production line needs 6-7 people to complete the production. Our company's product CNC program all for independent research and development, powerful automation function, in the case of increased equipment ,output greatly improved,the labor reduced by more than half,saving the labor management cost.Pre-sale service1) Provide the free consultation of equipment

2) Provide the standard device and the flow chart3) According to the clients' special requirement ,offering the resonable plan and free design to help to select the equipment .4)Welcome to visit our factoryService during the sales1) Inspect the machine before leaving the factory

2) Oversea install and debug the equipment3) Train the first-line operatorAfter sales service

1) 24 hours online service

2) Provide the VIDEO with install and debug the equipment3) Provide technical exchanging

FAQ

Q1:Can you customize products for clients?

A1: Yes We can customize and produce woodworking machines according to the customer's requirements or drawings.

Q2:What about your products quality?

A2:We can provide you samples for quality inspection. If you order, we guarantee the quality is same with sample. In case of quality problem, we can sign agreements and our company will perform the duties.

Q3:How can we trust your factory?

A3:We recommend that you come to our factory to see the goods,to verify the real situation of the products, and know more about our factory.

Q4:Why does the price often change?

A4:The price change is determined by various configurations such as motor and operating system. Different supporting equipments have different prices.

Q5:What about the contract signing?

A5: If you're satisfied with the products and our service, you can sign the contract with us, pay the deposit Then we'll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

Q6: How about delivery?

A: when the product is ready, it can be delivered to you after your full payment. We'll provide technical guidance.

Contact us

Details determine success. Service is only better, not the best; satisfaction is only a starting point, not an end point, we will use the most sincere attitude to choose the right product for you, welcome to consult and buy.

Related Products

-

![Woodworking Factory 3D Door Furniture Cabinet Wood Acrylic MDF Plywood Engraving Cutting Carving Milling Router Machine 1325 CNC Router]()

Woodworking Factory 3D Door Furniture Cabinet Wood Acrylic MDF Plywood Engraving Cutting Carving Milling Router Machine 1325 CNC Router

-

![Perfect Laser-10W 20W 30W 50W 100 Watts Desktop Metal Steel Raycus Max Ipg Jpt Mopa Fiber Laser Marker Engraver Etching Engraving Marking Machines]()

Perfect Laser-10W 20W 30W 50W 100 Watts Desktop Metal Steel Raycus Max Ipg Jpt Mopa Fiber Laser Marker Engraver Etching Engraving Marking Machines

-

![China Factory Cheap Price CO2/UV/Fiber Laser Marking Machine Price for Metal, Steel, Iron, Aluminum, PVC, Keyboard, Bearings Engraving]()

China Factory Cheap Price CO2/UV/Fiber Laser Marking Machine Price for Metal, Steel, Iron, Aluminum, PVC, Keyboard, Bearings Engraving

-

![Perfect Laser-20W 30W 50W 100 Watts Metal Stainless Steel Brass Ipg/Raycus/Max/Jpt/Mopa Wuhan Fiber CNC Laser Marker Engraving Marking Etching Machines Price]()

Perfect Laser-20W 30W 50W 100 Watts Metal Stainless Steel Brass Ipg/Raycus/Max/Jpt/Mopa Wuhan Fiber CNC Laser Marker Engraving Marking Etching Machines Price